3D Printer

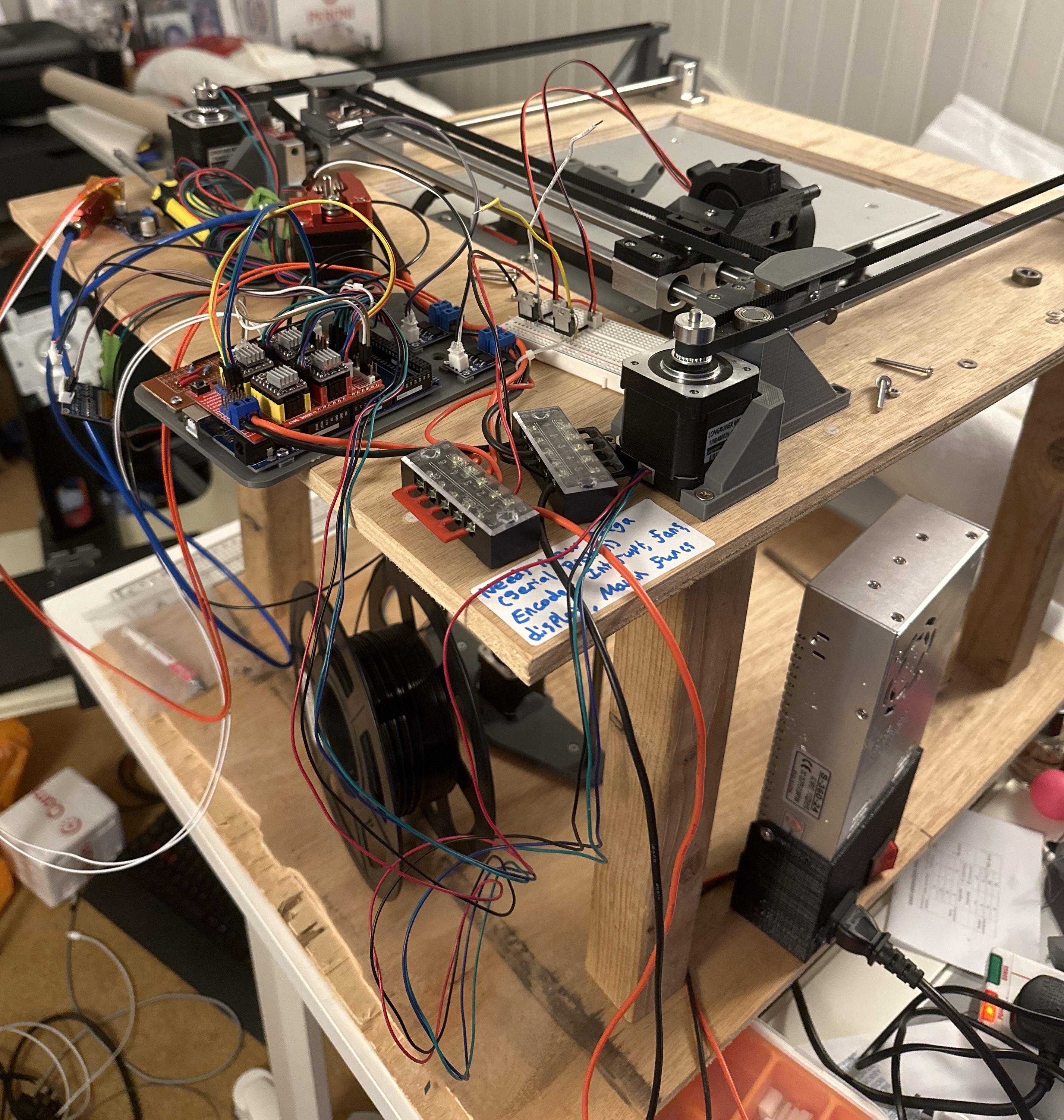

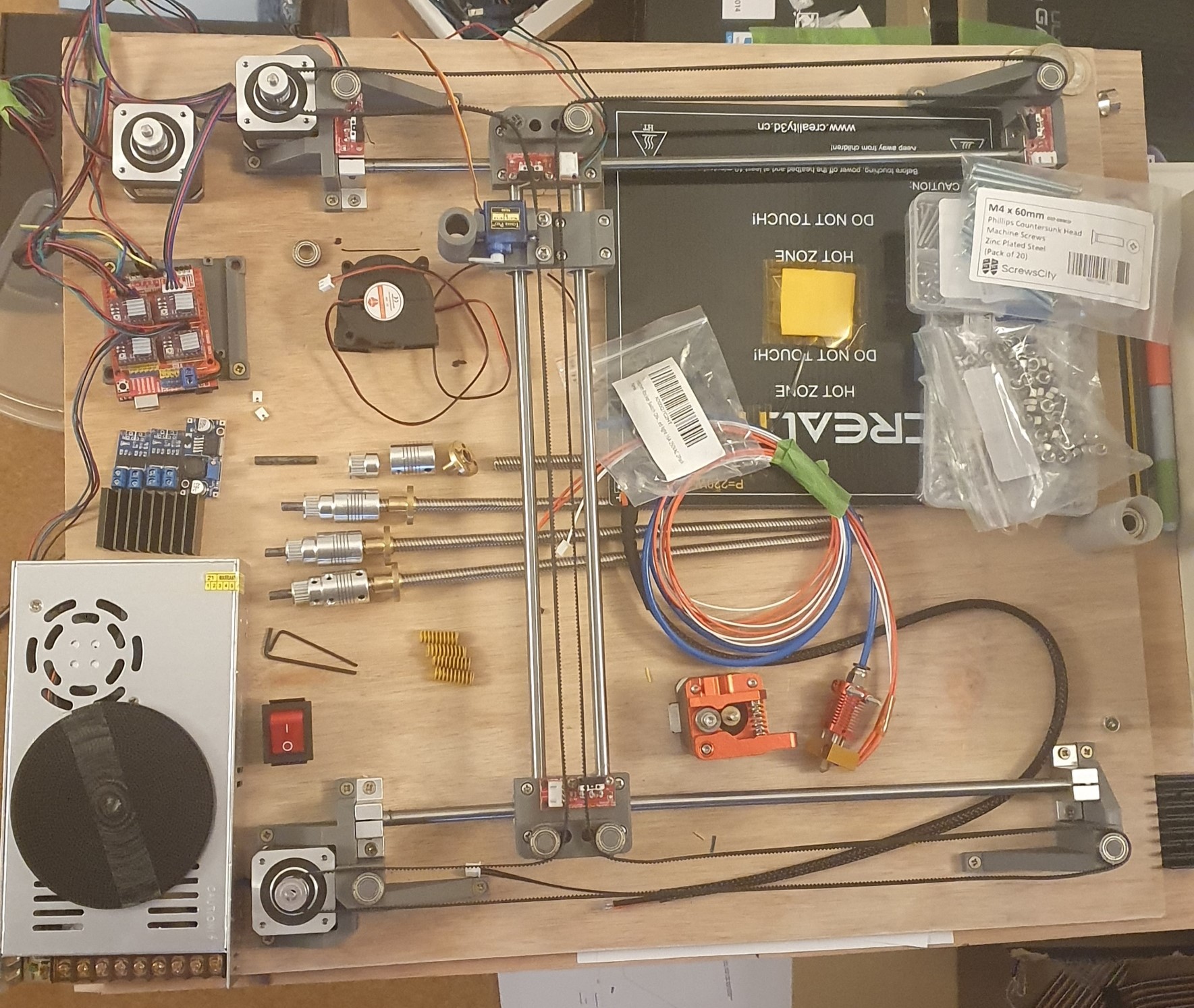

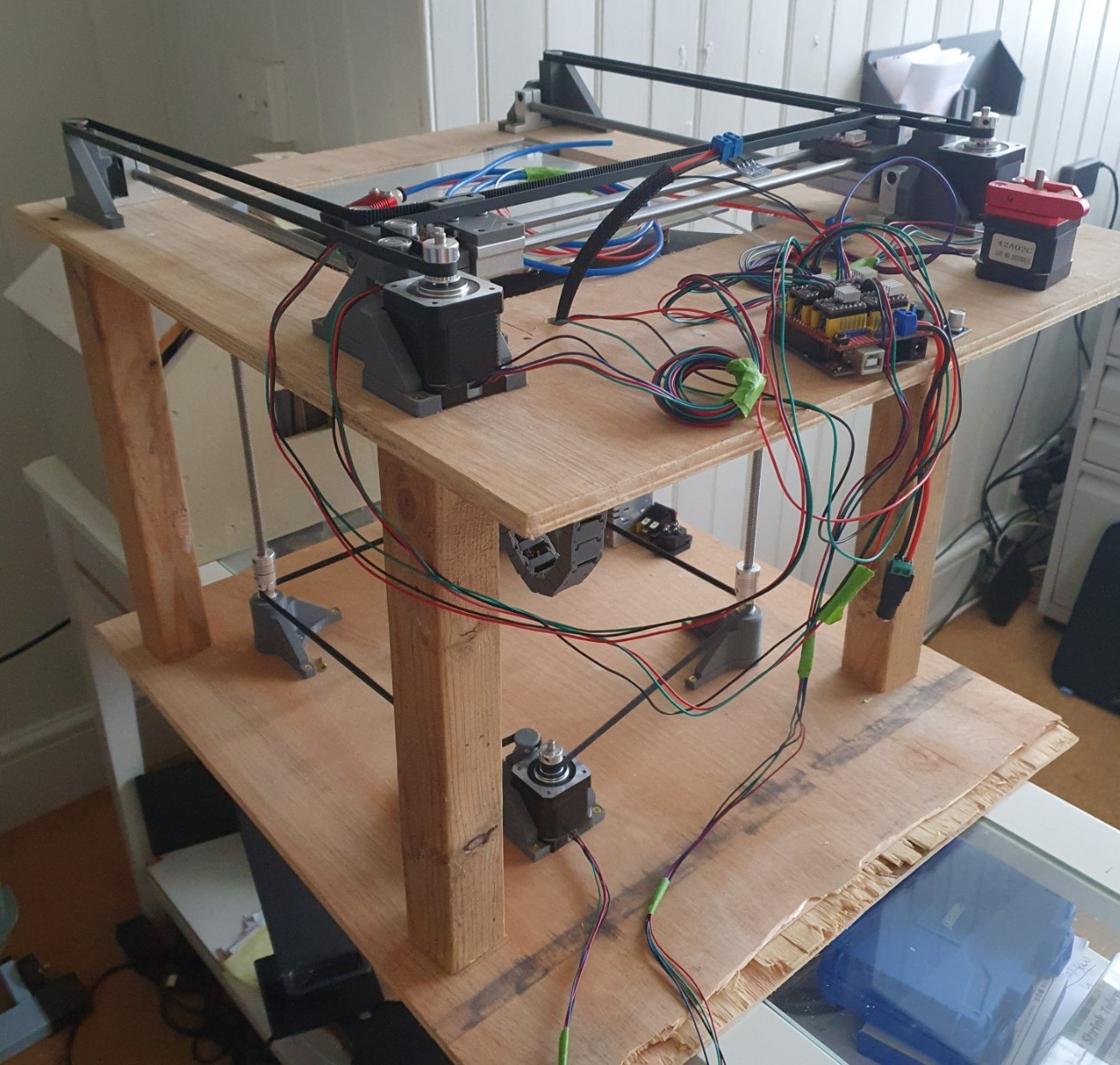

Work in progress 3D Printer made from original drawing machine

Adding 3rd axis to drawing machine

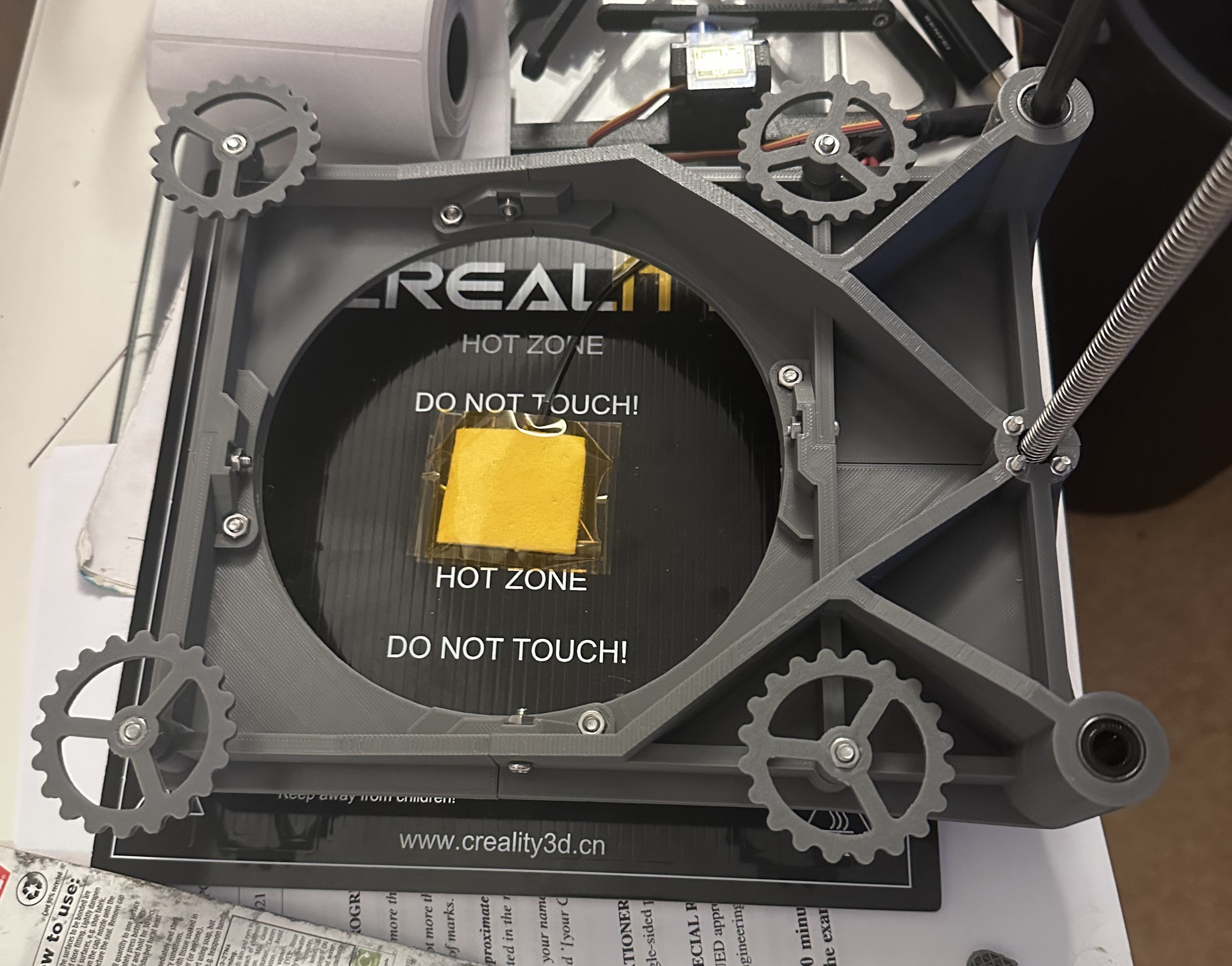

4 screw design

The 3D printed material under the weight of the heated plate could deflect much more than the nozzle height. For this reason I thought it would be best if all 4 corners were supported. The design shown below shows that with 4 threads all connected by a belt to a motor.

This design was a big failure though as the belt kept slipping. Despite using a stronger belt tensioner, friction and small manufacturing deviations in thread positions still meant that there was more torque required than could be transferred by the belt.

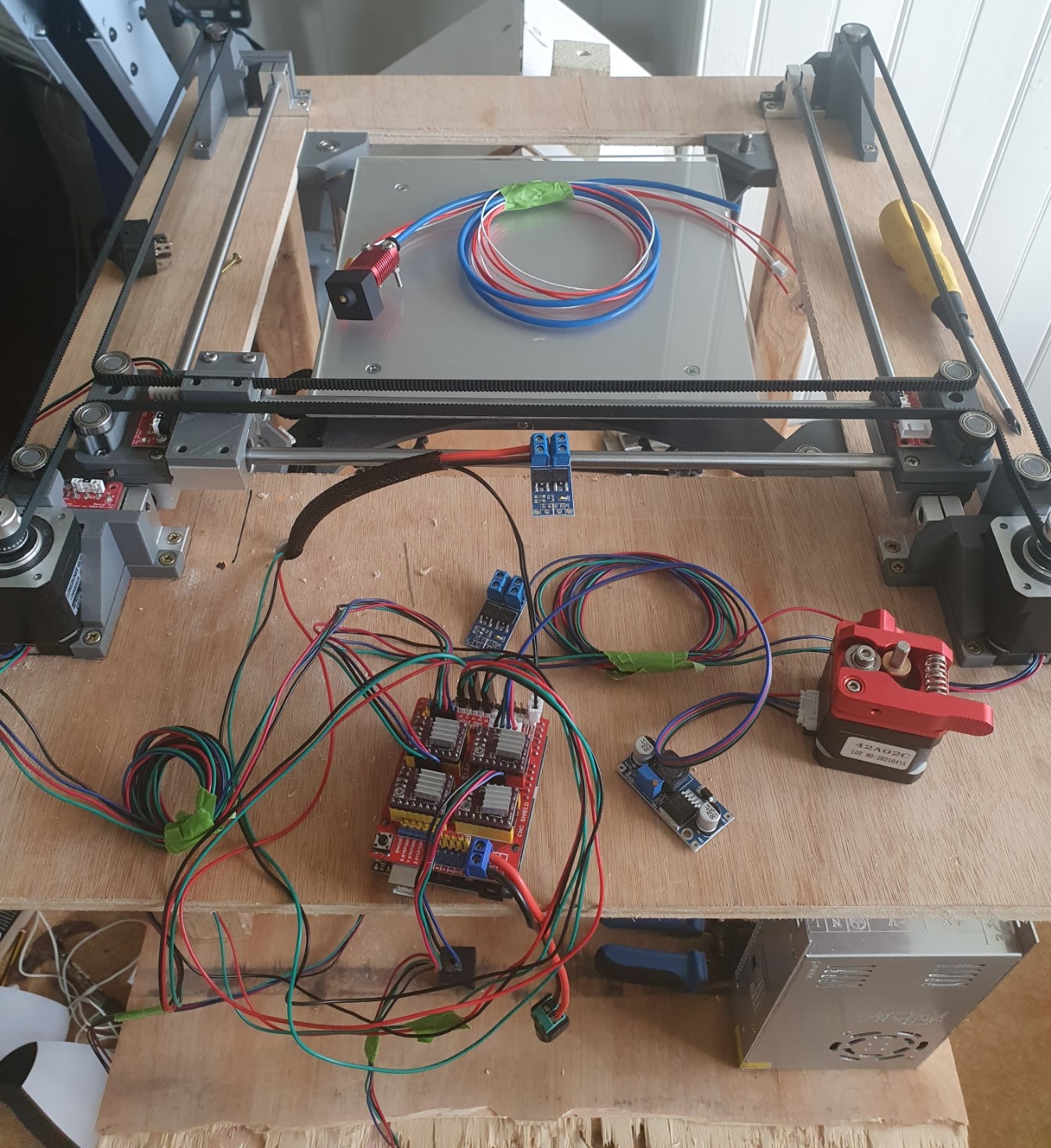

Change to a single thread

A single thread, with slider bearings on one side has worse deflection, however it reduces the problems mentioned earlier with friction deviations in the thread positions.