Resin Printer Setup

I’ve invested in a good resin printer for higher quality parts and moulds for future aerodynamic testing.

I had help to design and build a safe ventilated cupboard to use the printer in our attic.

Construction

The original plan was to buy a grow tent and extractor fan, however this was not possible in the tight attic space. This would have fit in a room in the house but would look awful and take up too much space. Instead, I decided to build a cupboard in the attic to keep the fumes away from the rest of the house.

Ventilator fan being setup on the floor of the cupboard to remove VOCs

Ventilator fan being setup on the floor of the cupboard to remove VOCs

The other side of the fan is connected to a manifold that fits between the roof and the wall of the house. This had to be print out of 2 parts and siliconed together.

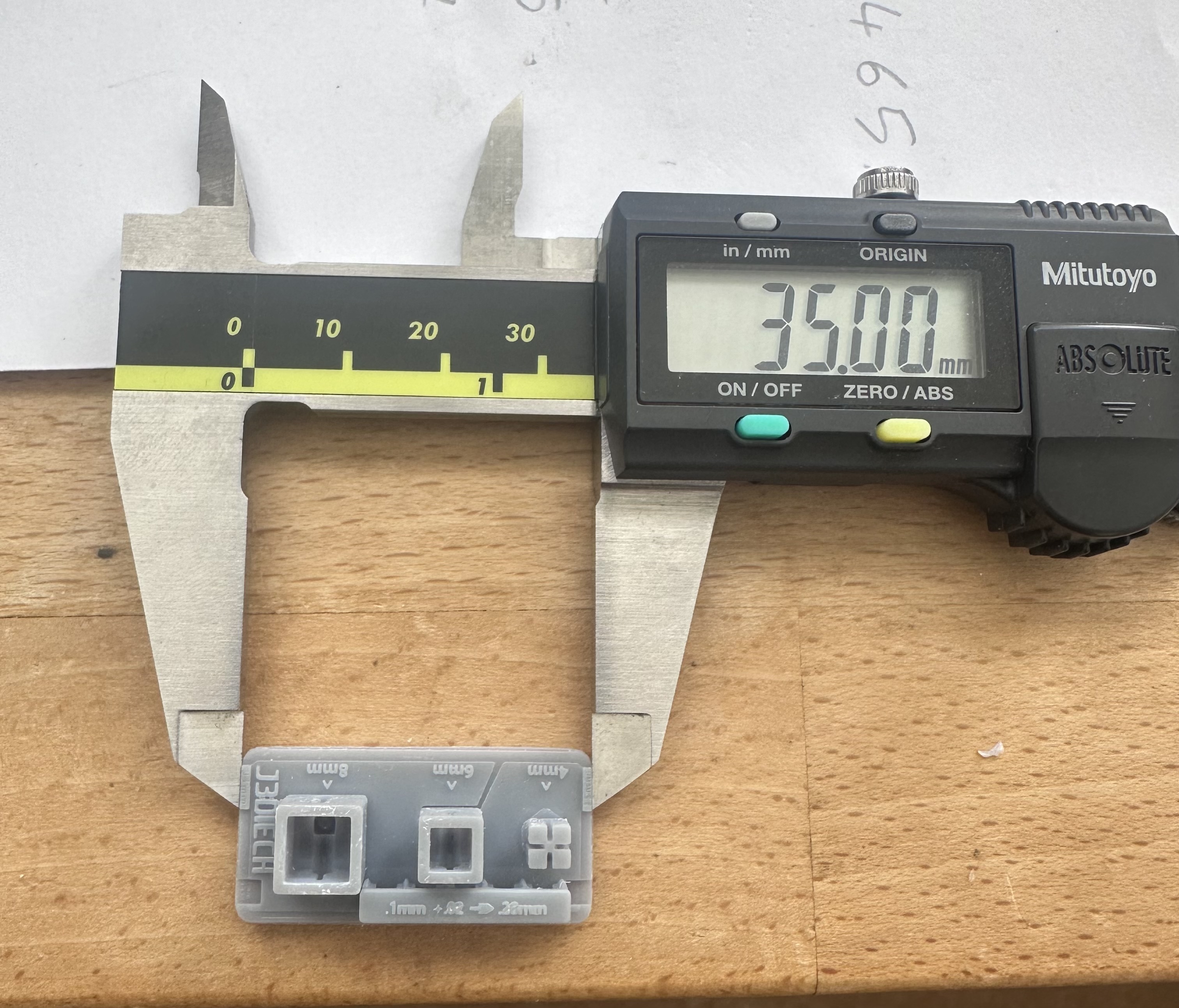

Calibration

The first print was a complete failure as the bottom exposure time was too short for the resin I was using. The layers above need a shorter time calibration and are important for dimensional accuracy which took a few tries to get right.

Despite the cupboard being well ventilated, a smell still lingers in the attic after printing. I make sure to wear a mask capable of filtering out VOCs when I’m in the attic.

This looks like a full on Breaking Bad mask so it makes for a good photo.